Root Cause Analysis

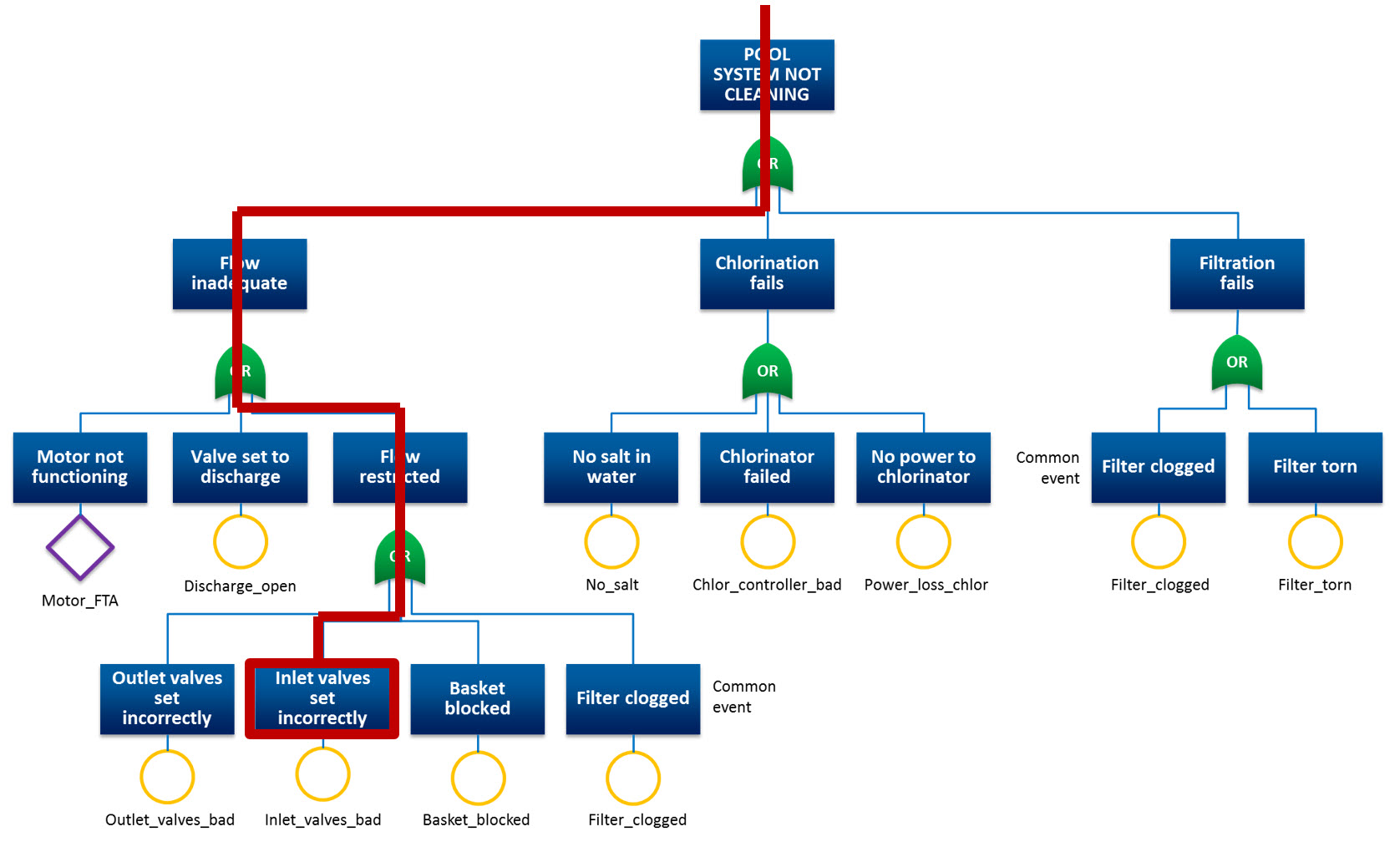

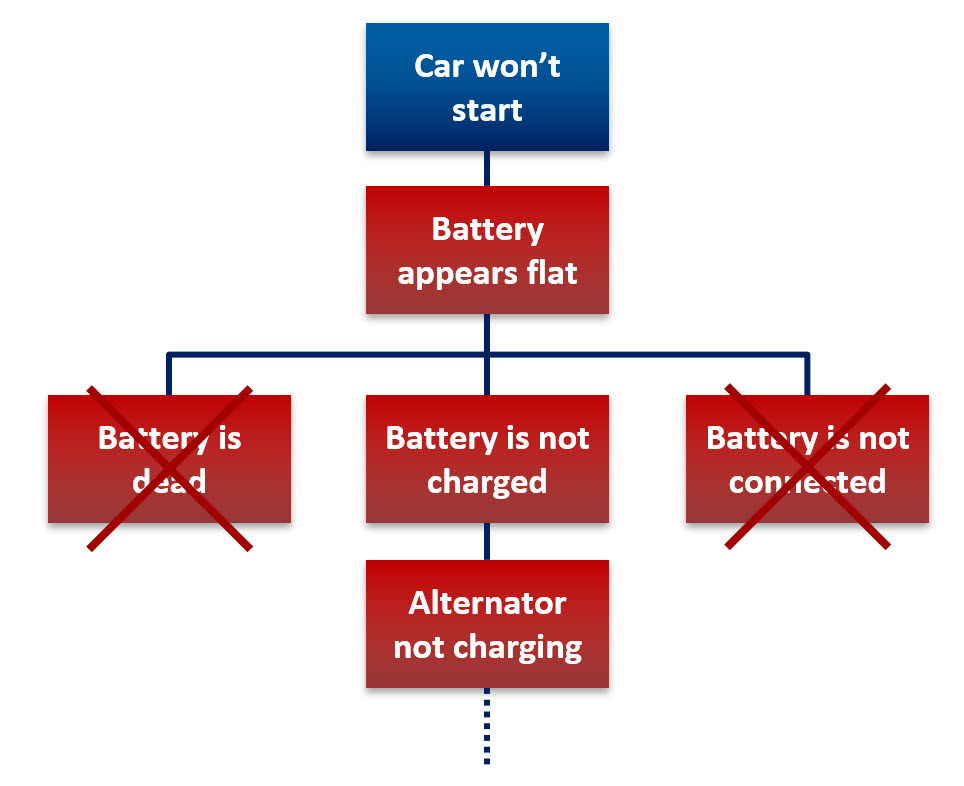

Topics covered: Root Cause Failure Analysis (RCFA) techniques, FRACAS, RCFA project management techniques, Fault Tree Analysis.

One of the keys to successful reliability improvement is getting to the bottom of a problem, finding the one (or more) actions that cause the problem, and solving it – stopping it from occurring again. This basic technique is most commonly applied to equipment failure, but it can, and should, be applied to other situations where the outcome is undesirable: poor performance, time or resources being wasted, the occurrence of near misses, and others.

But root cause analysis requires far more knowledge than simply understanding basic techniques such as “five why’s” and “fishbone”. You must also have project management skills to define the project, manage the root cause identification process, and manage the process of eliminating the root cause(s).

Therefore, this course covers both RCFA techniques (five why’s, fault tree analysis – with an extra module dedicated to FTA, Ishikawa/fishbone, STEP), FRACAS, and RCFA project management techniques (A3,8D, and 16J).

It is highly recommended that you also take the “CULTURE CHANGE, HUMAN BEHAVIOR, AND HUMAN ERROR” course. The root cause of most problems relates to what people do (or don’t do). You must get to the bottom of why they do (or don’t do) what is expected of them. In addition, when you are investigating the root cause of a failure (or any kind of problem), you will engage with people and request their support (to extract ‘evidence’, gain specialty knowledge, brainstorm ideas and solutions, and much more). If you are not aware of cognitive biases, and factors like peer group pressure, you will again struggle to be successful.

And finally, when it comes time to implement the improvement process (the solution to the problem) you will again engage with people – this can potentially backfire, and the solution will never be successfully implemented.

The bottom line is that you must understand people and sources of human error before you can be successful in the root cause analysis and solution process.

These lesson modules were taken from the Asset Reliability Practitioner® ARP-E course for Reliability Engineers, but almost everyone should have a solid understanding of root cause (failure) analysis, especially those involved with maintenance and condition monitoring.

Note that you will be credited with this course fee if you upgrade to the ARP-E course.

LANGUAGE: English

LESSONS: 6

DURATION: 3 hours

SUBSCRIPTION DURATION: 3 months

The course includes approximately 3 hours of video lessons, delivered by Jason Tranter, the founder, and CEO of Mobius Institute.