Asset Strategy Development

Topics covered: Asset strategy development, master asset list (MAL) and bill of materials (BOM), fault tree analysis, Failure Modes, Effects and Criticality Analysis (FMECA), Reliability Centered Maintenance (RCM), and Preventive Maintenance Optimization (PMO).

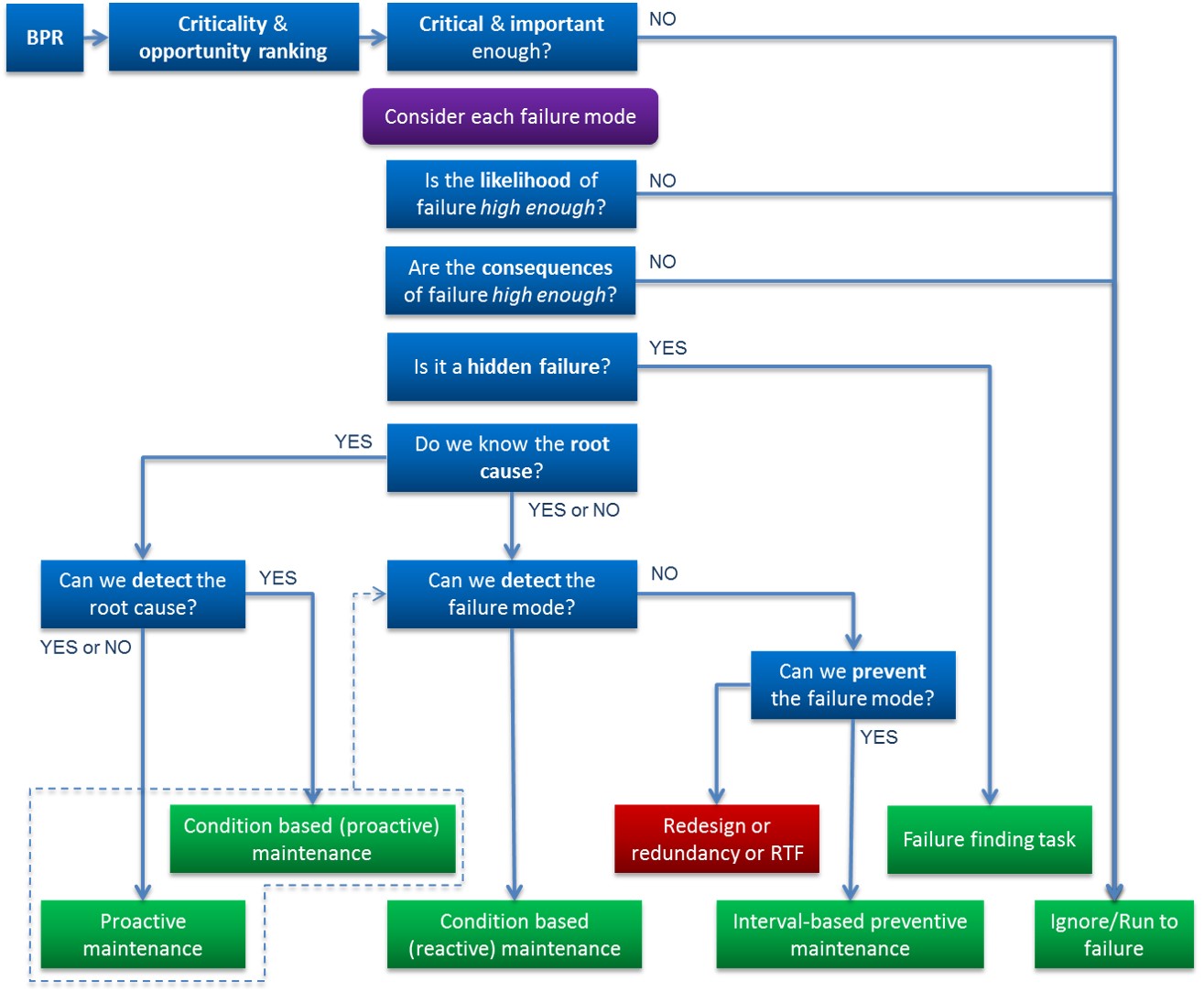

Every reliability (and maintenance) improvement program must utilize a technique that establishes an effective maintenance strategy: the right balance of condition-based maintenance, time-based maintenance, and other elements. Unfortunately, in many plants, the maintenance strategy (and the condition monitoring plan) simply evolve over time. As a result, there are tasks and tests performed that either adds no value, provide little value, or in some cases, actually harm the equipment.

In this course, you will learn how to develop an asset strategy. After a detailed overview of the process, and after describing some of the fundamental components that must be in place (a master asset list, bill of materials, a CMMS, etc.), we will cover four tools that will help you establish the asset strategy.

First, we will begin with a detailed summary of fault tree analysis (also known as causal tree analysis). While this technique is not used to develop the asset strategy specifically, it is a very powerful tool that supports FMECA and RCM (and RCA, which is covered in a separate course).

Next, we will discuss Failure Modes, Effects, and Criticality Analysis (FMECA). This is a very powerful tool that enables you to identify each of the tasks that must be performed to ensure that failures are kept to a minimum. This technique is often used when performing root cause analysis, and it should be used during the design phase of new projects to ensure that the lifecycle costs are kept to a minimum.

Next, we will all discuss Reliability Centered Maintenance (RCM). Many would argue that FMECA is a subset of RCM, but for sure, if you wish to be successful with RCM it helps a great deal to be familiar with FMECA.

And finally, we will cover Preventive Maintenance Optimization (PMO).

Where possible, our courses follow ISO and IEC International standards. Therefore, it is not Mobius Institute’s™ theory of RCM or FMECA that we will be discussing. It is based on international standards.

These lesson modules were taken from the Asset Reliability Practitioner® ARP-E course for Reliability Engineers, but this course will also be of interest to maintenance managers (and planners/schedulers) and the manager of the condition monitoring program.

Note that you will be credited with this course fee if you upgrade to the ARP-E course.

LANGUAGE: English

LESSONS: 35

DURATION: 8 hours

SUBSCRIPTION DURATION: 3 months

The course includes approximately 8 hours of video lessons, delivered by Jason Tranter, the founder, and CEO of Mobius Institute.

Please also note that the “ASSET CRITICALITY RANKING & PARETO ANALYSIS” course perfectly complements this course, and it is recommended that you take that course first. The Asset Criticality Ranking should be utilized to prioritize the work performed in this area.

Please also note that the “CONDITION MONITORING AND CONDITION-BASED MAINTENANCE” course also fits with this course as it should be defined based on your asset strategy.