Lubrication and Oil Analysis Dictionary

The field of lubrication and oil analysis is filled with technical terms, jargon, acronyms, and definitions. Use the dictionary as a resource to gain a clearer understanding of concepts and definitions

2-BODY ABRASIVE WEAR

Is caused by rubbing of a softer surface by a hard rough surface.

3-BODY ABRASIVE WEAR

Is caused by hard particles entrapped between two sliding surfaces.

ABRASION

A general wearing away of a surface by constant scratching, usually due to the presence of foreign matter such as dirt, grit, or metallic particles in the lubricant. It may also cause a breakdown of the material (such as the tooth surfaces of gears). Lack of proper lubrication may result in abrasion.

ABRASIVE WEAR

(or cutting wear) Comes about when hard surface asperities or hard particles that have embedded themselves into a soft surface plough grooves into the opposing harder surface, e.g., a journal.

ABSOLUTE FILTRATION RATING

The diameter of the largest hard spherical particle that will pass through a filter under specified test conditions. This is an indication of the largest opening in the filter elements.

ABSOLUTE PRESSURE

The sum of atmospheric and gauge pressure.

ABSOLUTE VISCOSITY

A term used interchangeably with viscosity to distinguish it from either kinematic viscosity or commercial viscosity. Absolute viscosity is the ratio of shear stress to shear rate. It is a fluid’s internal resistance to flow. The common unit of absolute viscosity is the poise. Absolute viscosity divided by fluid density equals kinematic viscosity. It is occasionally referred to as dynamic viscosity. Absolute viscosity and kinematic viscosity are expressed in fundamental units. Commercial viscosity such as Saybolt viscosity is expressed in arbitrary units of time, usually seconds.

ABSORBENT FILTER

A filter medium that holds contaminant by mechanical means.

ABSORPTION

The assimilation of one material into another; in petroleum refining, the use of an absorptive liquid to selectively remove components from a process stream.

AC FINE TEST DUST (ACFTD)

A test contaminant used to assess both filters and the contaminant sensitivity of all types of tribological mechanisms.

ACCUMULATOR

A container in which fluid is stored under pressure as a source of fluid power.

ACID

In a restricted sense, any substance containing hydrogen in combination with a nonmetal or nonmetallic radical and capable of producing hydrogen ions in solution.

ACID NUMBER

The quantity of base, expressed in milligrams of potassium hydroxide, that is required to neutralize the acidic constituents in 1 gram of sample.

ACIDITY

In lubricants, acidity denotes the presence of acid-type constituents whose concentration is usually defined in terms of total acid number. The constituents vary in nature and may or may not markedly influence the behavior of the lubricant.

ADDITIVE

A compound that enhances some property of, or imparts some new property to, the base fluid. In some hydraulic fluid formulations, the additive volume may constitute as much as 20 percent of the final composition. The more important types of additives include anti-oxidants, anti-wear additives, corrosion inhibitors, viscosity index improvers, and foam suppressants. Additive stability — the ability of additives in the fluid to resist changes in their performance during storage or use.

ADDITIVE LEVEL

The total percentage of all additives in an oil. Expressed in % of mass (weight) or % of volume.

ADHESION

The property of a lubricant that causes it to cling or adhere to a solid surface.

ADHESIVE WEAR

Is often referred to as galling, scuffing, scoring, or seizing. It happens when sliding surfaces contact one another, causing fragments to be pulled from one surface and to adhere to the other.

ADSORBENT FILTER

A filter medium primarily intended to hold soluble and insoluble contaminants on its surface by molecular adhesion.

ADSORPTION

Adhesion of the molecules of gases, liquids, or dissolved substances to a solid surface, resulting in relatively high concentration of the molecules at the place of contact; e.g. the plating out of an anti-wear additive on metal surfaces.

ADSORPTIVE FILTRATION

The attraction to, and retention of particles in, a filter medium by electrostatic forces, or by molecular attraction between the particles and the medium.

AERATION

The state of air being suspended in a liquid such as a lubricant or hydraulic fluid.

A.G.M.A

Abbreviation for “American Gear Manufacturers Associations,” an organization serving the gear industry. A voluntary association of companies, consultants, and academicians with a direct interest in the design, manufacture, and application of gears, couplings and related power transmissions components and equipment.

AGGLOMERATION

The potential of the system for particle attraction and adhesion.

AIR BREATHER

A device permitting air movement between atmosphere and the component in/on which it is installed.

AIR ENTRAINMENT

The incorporation of air in the form of bubbles as a dispersed phase in the bulk liquid. Air may be entrained in a liquid through mechanical means and/or by release of dissolved air due to a sudden change in environment.

AIR MOTOR

A device which converts compressed gas into mechanical force and motion. It usually provides rotary mechanical motion.

AIR, COMPRESSED

Air at any pressure greater than atmospheric pressure.

ALKALI

Any substance having basic properties (as contrasted with acidic properties). In a restricted sense it is applied to the hydroxides of ammonium, lithium, potassium, and sodium. Alkaline materials in lubricating oils neutralize acids to prevent acidic (corrosive) wear in internal combustion engines. Examples are lime, soda ash, milk of magnesia, and baking soda.

AMBIENT TEMPERATURE

Temperature of the area or atmosphere around a process, not the operating temperature of the process itself.

AMERICAN NATIONAL STANDARDS INSTITUTE (ANSI)

An organization intended to establish terminologies, improve methods of testing, rating, and analysis, and represent US interests in internationals standards work.

AMERICAN PETROLEUM INSTITUTE (API)

Organization to enhance the interests of the petroleum industry, including to provide clear information, conduct research, and develop and maintain the API Service Classifications for crankcase oils.

AMERICAN PETROLEUM INSTITUTE CERTIFICATION

Engine service classification for gasoline and diesel engine oil quality levels, established jointly by API, SAE, and ASTM. Sometimes called SAE or API/SAE categories; formerly called API Engine Service Classifications.

AMERICAN PETROLEUM INSTITUTE GRAVITY

A gravity scale established by the American Petroleum Institute and in general use in the petroleum industry. See API Gravity.

ANALYTICAL FERROGRAPHY

The magnetic precipitation and subsequent analysis of wear debris from a fluid sample. This approach involves passing a volume of fluid over a chemically treated microscope slide which is supported over a magnetic field. Permanent magnets are arranged in such a way as to create a varying field strength over the length of the substrate. This varying strength causes wear debris to precipitate in a distribution with respect to size and mass over the Ferrogram. Once rinsed and fixed to the substrate, this debris deposit serves as an excellent media for optical analysis of the composite wear particulates.

ANHYDROUS

Devoid of water.

ANILINE POINT

The minimum temperature for complete miscibility of equal volumes of aniline and the sample under test ASTM Method D 611. A product of high aniline point will be low in aromatics and naphthenes and, therefore, high in paraffins. Aniline point is often specified for spray oils, cleaning solvents, and thinners, where effectiveness depends upon aromatic content.

ANTI-FOAM AGENT

One of two types of additives used to reduce foaming in petroleum products: silicone oil to break up large surface bubbles, and various kinds of polymers that decrease the amount of small bubbles entrained in the oils.

ANTI-FRICTION (AF) BEARING

A rolling contact type bearing in which the rotating or moving member is supported or guided by means of ball or roller elements. Does not mean without friction.

ANTI-OXIDANTS (OXIDATION INHIBITORS)

Prolong the induction period of a base oil in the presence of oxidizing conditions and catalyst metals at elevated temperatures. The additive is consumed and degradation products increase not only with increasing and sustained temperature, but also with increases in mechanical agitation or turbulence and contamination — air, water, metallic particles, and dust.

ANTISTATIC ADDITIVE

An additive that increases the conductivity of a hydrocarbon fuel to hasten the dissipation of electrostatic charges during high-speed dispensing, thereby reducing the fire/explosion hazard.

ANTIWEAR ADDITIVES

Improve the service life of tribological elements operating in the boundary lubrication regime. Antiwear compounds (for example, ZDDP and TCP) start decomposing at 90° to 100°C and even at a lower temperature if water (25 to 50 ppm) is present.

API ENGINE SERVICE CATEGORIES

Gasoline and diesel engine oil quality levels established jointly by API, SAE, and ASTM, and sometimes called SAE or API/SAE categories; formerly called API Engine Service Classifications.

API GRAVITY

A gravity scale established by the American Petroleum Institute and in general use in the petroleum industry, the unit being called “the A.P.I. degree.” This unit is defined in terms of specific gravity as follows:

API ° = (141.5 ÷ specific gravity at 60/60°F) – 131.5

The notation 60/60°F specifies a density measured at 60°F and referenced to water at 60°F. The density of water at one atmosphere and 60°F is 62.368 lbm/ft3 or 999.04 kg/m3.

APPARENT VISCOSITY

The ratio of shear stress to rate of shear of a non-Newtonian fluid such as lubricating grease, or a multi-grade oil, calculated from Poiseuille’s equation and measured in poises. The apparent viscosity changes with changing rates of shear and temperature and must, therefore, be reported as the value at a given shear rate and temperature (ASTM Method D 1092).

AQUEOUS TOXICITY

Pass/Fail measure of a hydrocarbon’s toxicity. Rainbow trout test at 100 PPM lubricant. If more than 50% of the fish die, then the lubricant is toxic.

AROMATICS

Hydrocarbons containing a Benzene ring (six carbon, unsaturated ring) formation found in lubricant base stocks. Generally, this hydrocarbon is undesirable and is removed to the maximum extent possible. Unsaturated hydrocarbons, aromatics are usually more reactive and have higher solvency than paraffins or naphthene’s.

ARRHENIUS RULE

Law of thermal physics that describes how the oxidation rate of oil doubles for every 18°F temperature increase (generally starting at 140°F for mineral oils and 170°F for synthetics.)

ASH

A measure of the amount of inorganic material in lubricating oil. Determined by burning the oil and weighing the residue. Results expressed as percent by weight.

ASPERITIES

Microscopic projections on metal surfaces resulting from normal surface-finishing processes. Interference between opposing asperities in sliding or rolling applications is a source of friction, and can lead to metal welding and scoring. Ideally, the lubricating film between two moving surfaces should be thicker than the combined height of the opposing asperities.

A.S.T.M.

American Society for Testing and Materials. A society for developing standards for materials and test methods.

ATMOSPHERIC PRESSURE

Pressure exerted by the atmosphere at any specific location. (Sea level pressure is approximately 14.7 pounds per square inch absolute).

ATOMIC ABSORPTION SPECTROSCOPY

Measures the radiation absorbed by chemically unbound atoms by analyzing the transmitted energy relative to the incident energy at each frequency. The procedure consists of diluting the fluid sample with methyl isobutyl ketone (MIBK) and directly aspirating the solution. The actual process of atomization involves reducing the solution to a fine spray, dissolving it, and finally vaporizing it with a flame. The vaporization of the metal particles depends upon their time in the flame, the flame temperature, and the composition of the flame gas. The spectrum occurs because atoms in the vapor state can absorb radiation at certain well-defined characteristic wave lengths. The wave length bands absorbed are very narrow and differ for each element. In addition, the absorption of radiant energy by electronic transitions from ground to excited state is essentially an absolute measure of the number of atoms in the flame and is, therefore, the concentration of the element in a sample.

ATOMIZATION

The conversion of a liquid into a spray of very fine droplets.

AUTOMATIC TRANSMISSION FLUID (ATF)

Fluid for automatic, hydraulic transmissions in motor vehicles.

AXIAL-LOAD BEARING

A bearing in which the load acts in the direction of the axis of rotation. See Thrust Load.

BABBITT

A soft, white, non-ferrous alloy bearing material composed principally of copper, antimony, tin and lead.

BACK PRESSURE

The pressure encountered on the return side of a system.

BACTERIA

Microorganisms often composed of a single cell.

BACTERIACIDE

Additive included in the formulations of water-mixed cutting fluids to inhibit the growth of bacteria promoted by the presence of water, thus preventing odors that can result from bacterial action.

BAFFLE

A device to prevent direct fluid flow or impingement on a surface.

BALL BEARING

An antifriction rolling type bearing containing rolling elements in the form of balls.

BARREL

A unit of liquid volume of petroleum oils equal to 42 U.S. gallons or approximately 35 Imperial gallons.

BASE

A material which neutralizes acids. An oil additive containing colloidally dispersed metal carbonate, used to reduce corrosive wear.

BASE STOCK

The base fluid, usually a refined petroleum fraction or a selected synthetic material, into which additives are blended to produce finished lubricants.

BEARING

Support or guide by means of which a moving part such as a shaft or axle is positioned with respect to the other parts of a mechanism.

BETA RATING

The method of comparing filter performance based on efficiency. This is done using the Multi-Pass Test which counts the number of particles of a given size before and after fluid passes through a filter.

BETA RATIO (ß-Ratio)

The ratio of the number of particles greater than a given size in the influent fluid to the number of particles greater than the same size in the effluent fluid, under specified test conditions (see “Multi-Pass Test”).

BEVEL GEAR

A straight-toothed gear with the teeth cut on sloping faces and the gear shafts at an angle (normally at a right angle).

BIOCIDES

Additive designed to inhibit the growth of microorganisms in liquids.

BIODEGRADABILITY

Measure of a lubricant’s ability to readily degrade under the force of naturally occurring micro-organisms.

BIODEGRADATION

The chemical breakdown of materials by living organisms in the environment. The process depends on certain microorganisms such as bacteria, yeast, and fungi, which breakdown molecules for sustenance. Certain chemical structures are more susceptible to microbial breakdown than others; vegetable oils, for example, will biodegrade more rapidly than petroleum oils.

BITUMEN

Also called asphalt or tar, bitumen is the brown or black viscous residue from the vacuum distillation of crude petroleum. It also occurs in nature as asphalt “lakes” and “tar sands.” It consists of high molecular weight hydrocarbons and minor amounts of sulfur and nitrogen compounds.

BLACK OILS

Lubricants containing asphaltic materials, which impart extra adhesiveness, that are used for open gears and steel cables.

BLEEDING / BLEED RATE

Separation of oil from grease structure. A certain amount of bleeding is desirable in greases since it tends to provide continuous oil lubrication to bearings.

BLOCKED PENETRATION

Is the penetration of a grease block (hard enough to hold its shape without a container).

BLOWBY

Passage of unburned fuel and combustion gases past the piston rings of internal combustion engines, resulting in fuel dilution and contamination of the crankcase oil.

BOILING POINT

The temperature at which a substance boils or is converted into vapor by bubbles forming within the liquid; it varies with pressure.

BOILING RANGE

For a mixture of substances, such as a petroleum fraction, the temperature interval between the initial and final boiling points.

BOMB OXIDATION

A test for the oxidation stability of a product obtained by sealing it in a closed container (Bomb) with pressurized oxygen.

BOUNDARY LUBRICATION

A form of lubrication between two rubbing surfaces without development of a full-fluid lubricating film. Boundary lubrication can be made more effective by including additives in the lubricating oil that provide a stronger oil film, thus preventing excessive friction and possible scoring. There are varying degrees of boundary lubrication, depending on the severity of service. For mild conditions, oiliness agents may be used; by plating out on metal surfaces in a thin but durable film, oiliness agents prevent scoring under some conditions that are too severe for a straight mineral oil. Compounded oils, which are formulated with polar fatty oils, are sometimes used for this purpose. Anti-wear additives are commonly used in more severe boundary lubrication applications. The more severe cases of boundary lubrication are defined as extreme pressure conditions; they are met with lubricants containing EP additives that prevent sliding surfaces from fusing together at high local temperatures and pressures.

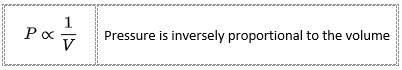

BOYLE’S LAW

The absolute pressure exerted by a given mass of an ideal gas is inversely proportional to the volume it occupies if the temperature and amount of gas remain unchanged within a closed system. Mathematically, Boyle’s law can be stated as:

or

where P is the pressure of the gas, V is the volume of the gas, and k is a constant.

Boyle’s law states that when the temperature of a given mass of confined gas is constant, the product of its pressure and volume is also constant. When comparing the same substance under two different sets of conditions, the law can be expressed as:

showing that as volume increases, the pressure of a gas decreases proportionally, and vice versa.

BRANCHED PARAFFIN

Common molecule form for a mineral oil base stock.

BREAKDOWN MAINTENANCE

Maintenance performed after a machine has failed to return it to an operating state.

BRIDGING

A condition of filter element loading in which contaminant spans the space between adjacent sections of a filter element, thus blocking a portion of the useful filtration.

BRIGHT STOCK

A heavy residual lubricant stock with low pour point, used in finished blends to provide good bearing film strength, prevent scuffing, and reduce oil consumption. Usually identified by its viscosity, SUS at 210°F or cSt at 100°C.

BRINELLING

Permanent deformation of the bearing surfaces where the rollers (or balls) contact the races. Brinelling results from excessive load or impact on stationary bearings. It is a form of mechanical damage in which metal is displaced or upset without attrition.

BROOKFIELD VISCOSITY

Apparent viscosity in cP determined by a Brookfield viscometer, which measures the torque required to rotate a spindle at constant speed in oil of a given temperature. Basis for ASTM Method D 2983; used for measuring low temperature viscosity of lubricants.

BTU

British thermal unit. The amount of heat required to raise the temperature of 1 pound of water 1 degree Fahrenheit.

BUBBLE POINT

The differential gas pressure at which the first steady stream of gas bubbles is emitted from a wetted filter element under specified test conditions.

BUILT-IN DIRT

Material passed into the effluent stream composed of foreign materials incorporated into the filter medium.

BULK MODULUS (of elasticity)

A ratio of normal stress to a change in volume, also a term used in determining the compressibility of a fluid. Data for petroleum products can be found in the International Critical Tables.

BUNA-N

Buna-N is a copolymer of butadiene and acetonitrile.

BURST PRESSURE RATING

The maximum specified inside-out differential pressure that can be applied to a filter element without outward structural or filter-medium failure.

BUSHING

A short, extremely threaded connector with a smaller size internal thread.

BYPASS FILTRATION

A system of filtration in which only a portion of the total flow of a circulating fluid system passes through a filter at any instant or in which a filter having its own circulating pump operates in parallel to the main flow.

BYPASS VALVE (RELIEF VALVE)

A valve mechanism that assures system fluid flow when a preselected differential pressure across the filter element is exceeded; the valve allows all or part of the flow to bypass the filter element.

CAFE

Corporate Average Fuel Economy

CAMS

Eccentric shafts are used in most internal combustion engines to open and close valves.

CAPACITY

The amount of contaminants a filter will hold before an excessive pressure drop is caused. Most filters have bypass valves which open when a filter reaches its rated capacity.

CAPILLARITY

A property of a solid-liquid system manifested by the tendency of the liquid in contact with the solid to rise above or fall below the level of the surrounding liquid; this phenomenon is seen in a smallbore (capillary) tube.

CAPILLARY VISCOMETER

A viscometer in which the oil flows through a capillary tube.

CARBON

A non-metallic element – No. 6 in the periodic table. Diamonds and graphite are pure forms of carbon. Carbon is a constituent of all organic compounds. It also occurs in combined form in many inorganic substances; i.e., carbon dioxide, limestone, etc.

CARBON (DEPOSIT)

Solid black residue in piston grooves which can interfere with piston ring movement leading to wear and/or loss of power.

CARBON RESIDUE

Coked material remaining after an oil has been exposed to high temperatures under controlled conditions.

CARBONYL IRON POWDER

A contaminant which consists of up to 99.5% pure iron spheres.

CASE DRAIN FILTER

A filter located in a line conducting fluid from a pump or motor housing to the reservoir.

CASE DRAIN LINE

A line conducting fluid from a component housing to the reservoir.

CARTRIDGE SEAL

A completely self-contained assembly including seal, gland, sleeve, mating ring, etc., usually needing no installation measurement.

CATALYST

A substance which speeds a chemical action without undergoing a chemical change itself during the process. Now used in catalytic converters to control amount of unburned hydrocarbons and CO in automobile exhaust.

CATALYTIC CONVERTER

An integral part of vehicle emission control systems since 1975. Oxidizing converters remove hydrocarbons and carbon monoxide (CO) from exhaust gases, while reducing converters control nitrogen oxide (NOx) emissions. Both use noble metal (platinum, palladium or rhodium) catalysts that can be “poisoned” by lead compounds in the fuel or lubricant.

CATALYTIC HYDROGENATION

Refining station where hydrogen atoms are fixed to molecules through a combination of pressure, temperature, and a catalyst bed (chemical accelerator).

CATASTROPHIC FAILURE

Sudden, unexpected failure of a machine resulting in considerable cost and downtime.

CAVITATION

Formation of an air or vapor pocket (or bubble) due to lowering of pressure in a liquid, often as a result of a solid body, such as a propeller or piston, moving through the liquid; also, the pitting or wearing away of a solid surface as a result of the collapse of a vapor bubble. Cavitation can occur in a hydraulic system as a result of low fluid levels that draw air into the system, producing tiny bubbles that expand explosively at the pump outlet, causing metal erosion and eventual pump destruction.

CAVITATION EROSION

A material-damaging process which occurs as a result of vaporous cavitation. “Cavitation” refers to the occurrence or formation of gas- or vapor- filled pockets in flowing liquids due to the hydrodynamic generation of low pressure (below atmospheric pressure). This damage results from the hammering action when cavitation bubbles implode in the flow stream. Ultra-high pressures caused by the collapse of the vapor bubbles produce deformation, material failure and, finally, erosion of the surfaces.

CELLULOSE MEDIA

A filter material made from plant fibers. Because cellulose is a natural material, its fibers are rough in texture and vary in size and shape. Compared to synthetic media, these characteristics create a higher restriction to the flow of fluids.

CENTIPOISE (CP)

A unit of absolute viscosity. 1 centipoise = 0.01 poise.

CENTISTOKE (CST)

A unit of kinematic viscosity. 1 centistoke = 0.01 stoke.

CENTRALIZED LUBRICATION

A system of lubrication in which a metered amount of lubricant or lubricants for the bearing surfaces of a machine or group of machines are supplied from a central location.

CENTRIFUGAL SEPARATOR

A separator that removes immiscible fluid and solid contaminants that have a different specific gravity than the fluid being purified by accelerating the fluid mechanically in a circular path and using the radial acceleration component to isolate these contaminants.

CERTIFIED LUBRICATION SPECIALIST (CLS)

Certification as set forth by STLE.

CHANNELING

The phenomenon observed among gear lubricants and greases when they thicken due to cold weather or other causes, to such an extent that a groove is formed through which the part to be lubricated moves without actually coming in full contact with the lubricant.

CHEMICAL STABILITY

The tendency of a substance or mixture to resist chemical change.

CHELATING AGENT

Class of chemicals that form soluble, complex molecules with certain metal ions, inactivating the ions so that they cannot normally react with other elements or ions to produce precipitates or scale.

CHIP CONTROL (Grit control, Last-chance) FILTER

A filter intended to prevent only large particles from entering a component immediately downstream.

CIRCULATING LUBRICATION

A system of lubrication in which the lubricant, after having passed through a bearing or group of bearings, is recirculated by means of a pump.

CIRCULATING SYSTEM

A lubricating system in which oil is recirculated from a central sump to the parts requiring lubrication and then returned to the sump.

CLAY FILTRATION

A refining process using Fuller’s Earth (activated clay), bauxite or other minerals to absorb minute solids from lubricating oil, as well as remove traces of water, acids, and polar compounds.

CLEANABLE

A filter element which, when loaded, can be restored by a suitable process, to an acceptable percentage of its original dirt capacity.

CLEAN ROOM

A facility or enclosure in which air content and other conditions (such as temperature, humidity, and pressure) are controlled and maintained at a specific level by special facilities and operating processes and by trained personnel.

CLEANABLE FILTER

A filter element which, when loaded, can be restored by a suitable process, to an acceptable percentage of its original dirt capacity.

CLEANLINESS LEVEL (CL)

A measure of relative freedom from contaminants.

CLEARANCE BEARING

A journal bearing in which the radius of the bearing surface is greater than the radius of the journal surface.

CLOUD POINT

The temperature at which waxy crystals in an oil or fuel form a cloudy appearance.

CMRP

Certified Maintenance and Reliability Professional as set forth by SMRP.

COALESCOR

A separator that divides a mixture or emulsion of two immiscible liquids using the interfacial tension between the two liquids and the difference in wetting of the two liquids on a particular porous medium.

COEFFICIENT OF FRICTION

The number obtained by dividing the friction force resisting motion between two bodies by the normal force pressing the bodies together.

COHESION

That property of a substance that causes it to resist being pulled apart by mechanical means.

COKING

The undesirable accumulation of carbon (coke) deposits in the internal combustion engine or in a refinery plant.

COLD CRANKING SIMULATOR (CCS)

An intermediate shear rate viscometer that predicts the ability of an oil to permit a satisfactory cranking speed to be developed in a cold engine.

COLLAPSE

An inward structural failure of a filter element which can occur due to abnormally high pressure drop (differential pressure) or resistance to flow.

COLLAPSE PRESSURE

The minimum differential pressure that an element is designed to withstand without permanent deformation.

COLORIMETRIC METHOD FOR ACID MEASUREMENT

Under the colorimetric method for determining the neutralization number (ASTM D 974), end point is identified by the change of a color indicator. This indicator exhibits one color above a specified pH value, another below. By this means, a total acid or strong base number can be determined with a p-naphtholbenzene indicator, while a strong acid number can be determined with a methyl orange indicator. Obviously, however, this method is not suitable for the investigation of dark-colored liquids.

COMPATIBILITY

Measure of the degree that two or more lubricants can be mixed without the loss of performance or acceleration of harmful chemical reactions, leading to the destruction of the lubricant.

COMPLEX GREASE

A lubricating grease thickened by a complex soap. Complex soaps are created through the use of two organic acids (instead of one) and a metallic hydroxide. Complex greases typically have 500°F + dropping points.

COMPOUND

(1) Chemically speaking, a distinct substance formed by the combination of two or more elements in definite proportions by weight and possessing physical and chemical properties different from those of the combining elements. (2) In petroleum processing, generally connotes fatty oils and similar materials foreign to petroleum added to lubricants to impart special properties.

COMPOUNDED OIL

A petroleum oil to which has been added other chemical substances.

COMPOUNDING

The addition of fatty oils and similar materials to lubricants to impart special properties. Lubricating oils to which such materials have been added are known as compounded oils.

COMPRESSED AIR

Air at any pressure greater than atmospheric pressure.

COMPRESSIBILITY

The change in volume of a unit volume of a fluid when subjected to a unit change of pressure.

COMPRESSION RATIO

In an internal combustion engine, the ratio of the volume of combustion space at bottom dead center to that at top dead center.

COMPRESSOR

A device which converts mechanical force and motion into pneumatic fluid power.

CONSISTENCY

The degree to which lubricating grease resists deformation under the application of force. Sometimes used qualitatively to denote viscosity of liquids. (See NLGI and worked penetration).

CONDITION BASED MAINTENANCE

Maintenance strategy where maintenance activities are planned around changing equipment health conditions.

CONTAMINANT

Any foreign or unwanted substance that can have a negative effect on system operation, life or reliability.

CONTAMINANT (Dirt, ACFTD) CAPACITY

The weight of a specified artificial contaminant that must be added to the influent to produce a given differential pressure across a filter at specified conditions. Used as an indication of relative service life.

CONTAMINANT FAILURE

Any loss of performance due to the presence of contamination. Two basic types of contamination failure are: Perceptible — gradual loss of efficiency or performance, and Catastrophic — dramatic, unexpected failure.

CONTAMINANT LOCK

A particle or fiber-induced jam caused by solid contaminants.

CONTAMINATION

Any substance in the oil that does not belong there. The most common contaminates include particles, water, air, fuel, soot, and even the incorrect lubricant.

CONTAMINATION CONTROL

Proactive condition management activity wherein all contaminants (liquid, solid, and gaseous) are prohibited from interaction with the targeted system. A broad subject which applies to all types of material systems (including both biological and engineering). It is concerned with planning, organizing, managing, and implementing all activities required to determine, achieve and maintain a specified contamination level.

COOLANT

A fluid used to remove heat. See Cutting fluid.

COPPER STRIP CORROSION

A qualitative measure of the tendency of a petroleum product to corrode pure copper.

CORE

The internal duct and filter media support.

CORRECTIVE MAINTENANCE (CM)

see Reactive Maintenance.

% CORREL

The percentage of peaks in the used oil infrared spectrum which match those in the reference oil. A sudden decrease in this value usually means that the oil was mixed with a different type.

CORROSION

The decay and loss of a metal due to a chemical reaction between the metal and its environment. It is a transformation process in which the metal passes from its elemental form to a combined (or compound) form.

CORROSION INHIBITOR

Additive for protecting lubricated metal surfaces against chemical attack by water or other contaminants. There are several types of corrosion inhibitors. Polar compounds wet the metal surface preferentially, protecting it with a film of oil. Other compounds may absorb water by incorporating it in a water-in-oil emulsion so that only the oil touches the metal surface. Another type of corrosion inhibitor combines chemically with the metal to present a non-reactive surface.

CORROSIVE WEAR

Removal of materials by degradation due to chemical reaction.

COUPLING

A straight connector for fluid lines.

COUPLING, QUICK DISCONNECT

A coupling which can quickly join or separate lines.

CP

Centipoise.

CRACKLE TEST

A method for detecting water in oils. A few drops of oil are put on a hot plate set to 425°F. If the drops pop or crackle, then water is deemed present. Generally, this indicates water somewhere near 200ppm or greater.

CRACKLING

The process whereby large molecules are broken down by the application of heat and pressure to form smaller molecules.

CRANKCASE OIL

Lubricant used in the crankcase of the internal combustion engine.

CROWN

The top of the piston in an internal combustion engine above the fire ring, exposed to direct flame impingement.

CRUDE OIL

The basic (primary) raw material used in the manufacturing of hydrocarbon compounds.

CRYOGENICS

The branch of physics relating to the production and effects of very low temperatures.

CST

Centistoke

CUTTING FLUID

Any fluid applied to a cutting tool to assist in the cutting operation by cooling, lubricating or other means.

CYCLE

A single complete operation consisting of progressive phases starting and ending at the neutral position.

CYCLIC FATIGUE

Fatigue caused by repetitive loading-unloading stresses to a metal surface.

CYLINDER

A device which converts fluid power into linear mechanical force and motion. It usually consists of a moveable element such as a piston and piston rod, plunger rod, plunger or ram, operating within a cylindrical bore.

CYLINDER OIL

A lubricant for independently lubricated cylinders, such as those of steam engines and air compressors; also, for lubrication of valves and other elements in the cylinder area. Steam cylinder oils are available in a range of grades with high viscosities to compensate for the thinning effect of high temperatures; of these, the heavier grades are formulated for super-heated and high-pressure steam, and the less heavy grades for wet, saturated, or low-pressure steam. Some grades are compounded for service in excessive moisture; see compounded oil. Cylinder oils lubricate on a once-through basis.

DEAERATOR

A separator that removes air from the system fluid through the application of bubble dynamics.

DEFECT ELIMINATION

A systematic process of eliminating the underlying factors (root causes) that lead to system failure.

DEFOAMANT

An additive (typically silicone based) used to help separate entrained air (bubbles) from bulk oil.

DEGAS

Removing air from a liquid, usually by ultrasonic and/or vacuum methods.

DEGRADATION

The progressive failure of a machine or lubricant.

DEHYDRATOR

A separator that removes water from the system fluid.

DELAMINATION WEAR

A complex wear process where a machine surface is peeled away or otherwise removed by forces of another surface acting on it in a sliding motion.

DEMULSIBILITY

The ability of a fluid that is insoluble in water to separate from water with which it may be mixed in the form of an emulsion.

DEMULSIFIER

An additive that promotes oil-water separation in lubricants that are exposed to water or steam.

DENSITY

The mass of a unit volume of a substance. Its numerical value varies with the units used.

DEPOSITS

Oil-insoluble materials that result from oxidation and decomposition of lube oil and contamination from external sources and engine blow-by. These can settle out on machine or engine parts. Examples are sludge, varnish, lacquer and carbon.

DEPTH FILTER

A filter medium that retains contaminants primarily within tortuous passages.

DESORPTION

Opposite of absorption or adsorption. In filtration, it relates to the downstream release of particles previously retained by the filter.

DETECTION FREQUENCY

Cycle or frequency for which a condition-based measurement method is executed for a given machine or component.

DETERGENT

In lubrication, either an additive or a compounded lubricant having the property of keeping insoluble matter in suspension thus preventing its deposition where it would be harmful. A detergent may also re-disperse deposits already formed.

DETERGENT OIL

A type of lubricating oil that contains detergents. These detergents are designed to clean and prevent the buildup of deposits.

DEWAXING

Removal of paraffin wax from lubricating oils to improve the low temperature characteristics.

DIELECTRIC STRENGTH

A measure of the ability of an insulating material to withstand electric stress (voltage) without failure. Fluids with high dielectric strength (usually expressed in volts or kilovolts) are good electrical insulators. (ASTM Designation D 877.)

DIESTERS

A type of synthetic lubricant base stock made from a reaction between an acid and an alcohol. This base stock is made from non-petroleum materials.

DIFFERENTAIL PRESSURE INDICATOR

An indicator which signals the difference in pressure between any two points of a system or a component.

DIFFERENTIAL PRESSURE RELIEF VALVE

A valve whose primary function is to limit differential pressure.

DIRECTIONAL CONTROL VALVE

A valve whose primary function is to direct or prevent flow through selected passages.

DIRECTIONAL CONTROL VALVE (SERVO)

A directional control valve which modulates flow or pressure as a function of its input signal.

DIRT CAPACTITY (DUST CAPACITY) (CONTAMINANT CAPACITY)

The weight of a specified artificial contaminant which must be added to the influent to produce a given differential pressure across a filter at specified conditions. Used as an indication of relative service life.

DISPERSANT

In lubrication, a term usually used interchangeably with detergent. An additive, usually nonmetallic (“ashless”), which keeps fine particles of insoluble materials in a homogeneous solution. Hence, particles are not permitted to settle out and accumulate.

DISPOSABLE

A filter element intended to be discarded and replaced after one service cycle.

DISSOLVED AIR

Air dispersed in oil to form a mixture and not readily drawn out of solution. Petroleum oils contain as much as 12% dissolved air.

DISSOLVED GASES

Those gases that enter into solution with a fluid and are neither free nor entrained gases.

DISSOLVED WATER

Water dispersed throughout the oil by individual water molecules, unrecognizable visually. Most oils can hold 200-600 ppm in dissolved state, depending on type, temperature, and age of the oil.

DISTILLATE

Cut or fraction taken from a distillation tower having a viscosity suitable for lubricant manufacturer.

DISTILLATION

The primary refining step, in which the crude is separated into various boiling range fractions in a distillation tower.

DISTILLATION METHOD (ASTM D-95)

A method involving distilling the fluid sample in the presence of a solvent that is miscible in the sample but immiscible in water. The water distilled from the fluid is condensed and segregated in a specially-designed receiving tube or tray graduated to directly indicate the volume of water distilled.

DN FACTOR

Also known as speed factor. Determined by multiplying the bore of a rolling element bearing by the RPM of the journal. DN can be used, in conjunction with operating temperature, to help determine the appropriate viscosity or the NLGI grade to be applied.

DOUBLE SEAL

Two mechanical seals designed to permit a liquid or gas barrier fluid between the seals mounted back-to-back or face-to-face.

DRIP FEED OILER

Also called Drop Feed Oiler. Device for once through lubrication, whereby the drip feed oiler delivers oil from the bottom of a reservoir to an application one drop at a time, with flow rate controlled by a needle valve at the top of the reservoir.

DROP TUBE SAMPLING

Method of pulling an oil sample by inserting a tube into a fill port or dipstick port and lowering the tube into the oil below. A small manual vacuum pump is used to extract the oil. While several issues make this not the best practice, it is very common especially in less sophisticated programs.

DROPPING POINT

The temperature at which a drop of material falls from the orifice of the test apparatus under the conditions of ASTM D 566-42. Not to be confused with “melting point”. Grease softens gradually over a wide temperature range; there is no abrupt melting. Dropping point is useful in determining a general operating temperature limit. Rule of thumb apply to 70°F below dropping point.

DRUM

A container with a capacity of 55 U.S. gallons.

DRY SUMP

A machine design in which oil is retained in a vessel below the lubricated components. The lubricant is re-supplied under force by a pump system to maintain effective oil supply.

DUAL-LINE SYSTEM

A positive displacement terminating (oil or grease) lubrication system that employs two main lines supplied from a pump connected to a 2-way (reverser) valve. Pressure in one main line (while the other is open to tank) causes the measuring piston(s) in the dual-line valve(s) to stroke in one direction dispensing lubricant to one group of lube points. Switching the 2-way (reverser) valve directs pump flow to the second main line and opens the first main line to tank. This allows pressure to build in the second main line causing the dual-line valve(s) measuring piston(s) to stroke back to their original position dispensing lubricant to a second group of lube points. The system is also called a parallel system. Each dual-line valve operates independently of any other in the system.

DUPLEX FILTER

An assembly of two filters with valving for selection of both filters.

DYNAMIC SEAL

A seal that moves due to axial or radial movement of the unit.

EFFLUENT

The fluid leaving a component.

ELASTIC DEFORMATION

aka; Plastic Deformation. A phenomenon whereby the surfaces of rotating elements in contact, such as rolling element bearings and gear teeth, tend to deform slightly. As the metal surfaces deform somewhat, sub surface fatigue cracks may develop.

ELASTOHYDRODYNAMIC (EHD) LUBRICATION

In rolling element bearings, the elastic deformation of the bearing (flattening) as it rolls, under load, in the bearing race. This momentary flattening improves the hydrodynamic lubrication properties by converting point or line contact to surface-to-surface contact.

ELASTOMER

A rubber or rubber-like material, both natural and synthetic, used in making a wide variety of products, such as seals and hoses. In oil seals, an elastomer’s chemical composition is a factor in determining its compatibility with a lubricant.

ELECTROSTATIC SEPARATOR

A separator that removes contaminant from dielectric fluids by applying an electrical charge to the contaminant that is then attracted to a collection device of different electrical charge.

ELEMENT (CARTRIDGE)

The porous device that performs the actual process of filtration.

EMISSION SPECTROMETER

Works on the basis that atoms of metallic and other particular elements emit light at characteristic wavelengths when they are excited in a flame, arc, or spark. Excited light is directed through an entrance slit in the spectrometer. This light penetrates the slit, falls on a grate, and is dispersed and reflected. The spectrometer is calibrated by a series of standard samples containing known amounts of the elements of interest. By exciting these standard samples, an analytical curve can be established which gives the relationship between the light intensity and its concentration in the fluid.

EMULSIBILITY

The ability of a non-water-soluble fluid to form an emulsion with water.

EMULSIFIED WATER

Water suspended in oil in microscopic droplets after the saturation point has been reached. Often seen as cloudy or milky appearing oil.

EMULSIFIER

Additive that promotes the formation of a stable mixture, or emulsion, of oil and water. Common emulsifiers are: metallic soaps, certain animal and vegetable oils, and various polar compounds.

EMULSION

An intimate mixture of oil and water – generally milky appearance. Can be desirable or undesirable depending on the application. Emulsions may be of two types: oil-in-water (where water is the continuous phase) and water-in-oil (where water is the discontinuous phase).

END CAP

A ported or closed cover for the end of a filter element.

ENGINE DEPOSITS

Hard or persistent accumulation of sludge, varnish and carbonaceous residues due to blow-by of unburned and partially burned fuel, or the partial breakdown of the crankcase lubricant. Water from the condensation of combustion products, carbon, residues from fuel or lubricating oil additives, dust and metal particles also contribute.

ENTRAINED AIR

Minute bubbles in oil in a colloidal-like suspension giving the oil a cloudy or hazy appearance. Entrained air can disrupt or weaken the lubricating film and lead to excessive wear. The compressibility of the entrained air may also cause erratic and inefficient hydraulic operations.

ENVIRONMENTAL CONTAMINANT

All material and energy present in and around an operating system, such as dust, air moisture, chemicals, and thermal energy.

EROSIVE WEAR

Wear caused by particle impingement at high velocities or by cavitation, progressively removing machine surface.

EROSION

The progressive removal of a machine surface by cavitation or by particle impingement at high velocities.

ETHYLENE OXIDE

A raw material component used to manufacture Polyethylene Glycol (PAG) synthetic base stock.

EVAPORATION

Loss of liquid through conversion to gas phase. Light hydrocarbons tend to evaporate from the surfaces of hot lubricant sumps, eventually leading to viscosity thickening.

EXTREME PRESSURE (EP)

Lubricants that impart to rubbing surfaces the ability to carry appreciably greater loads than would be possible with ordinary lubricants without excessive wear or damage.

EXTREME PRESSURE (EP) ADDITIVE

Lubricant additive that prevents sliding metal surfaces from seizing under conditions of extreme pressure. At the high local temperatures associated with metal-to-metal contact, an EP additive combines chemically with the metal to form a surface film that prevents the welding of opposing asperities, and the consequent scoring that is destructive to sliding surfaces under high loads. Reactive compounds of sulfur, chlorine, or phosphorus are used to form these inorganic films.

EXTREME PRESSURE AGENT

Lubricant additive that prevents sliding metal surfaces from seizing under conditions of extreme pressure. At the high local temperatures associated with metal-to-metal contact, an EP additive combines chemically with the metal to form a surface film that prevents the welding of opposing asperities and the consequent scoring that is destructive to sliding surfaces under high loads. Reactive compounds of sulfur, phosphorus, inorganic metals, and chlorine are used to form these inorganic films.

EXTREME PRESSURE (EP) LUBRICANTS

Oils or greases to which EP agents have been added to impart load carrying or anti-weld qualities. Normally, an EP lubricant has a Timken O.K. Load of 35 lbs. or higher. Equipment manuals will often specify the use of EP grease, EP gear oil, or EP Industrial Oil.

FABRICATION INTEGRITY POINT

The differential gas pressure at which the first stream of gas bubbles are emitted from a wetted filter element under standard test conditions.

FACE SEAL

A device that prevents leakage of fluids along rotating shafts. Sealing is accomplished by a stationary primary seal ring bearing against the face of a mating ring mounted on a shaft. Axial pressure maintains the contact between the seal ring and the mating ring.

FAILURE MODES EFFECTS ANALYSIS (FMEA)

Analytical process designed to show the relationship between failure states (failure mode) and their manifested final conditions. Also known as FMEA.

FALEX EP TEST

Test designed to measure the EP characteristics of a lubricant under sliding frictional conditions. Consists of a rotating pin held in a V-block while submerged in oil. The load is gradually increased on the pin until the pin breaks or seizes.

FALSE BRINELLING

False brinelling of needle roller bearings is actually a fretting corrosion of the surface since the rollers are the I.D. of the bearing. Although its appearance is similar to that of brinelling, false brinelling is characterized by attrition of the steel, and the load on the bearing is less than that required to produce the resulting impression. It is the result of a combination of mechanical and chemical action that is not completely understood, and occurs when a small relative motion or vibration is accompanied by some loading, in the presence of oxygen.

FATIGUE CHUNKS

Thick three-dimensional particles exceeding 50 microns indicating severe wear of gear teeth.

FATIGUE PLATELETS

Normal particles between 20 and 40 microns found in gear box and rolling element bearing oil samples observed by analytical ferrography. A sudden increase in the size and quantity of these particles indicates excessive wear.

FATIGUE WEAR

Wear caused by repetitive stress. Often this wear starts as sub-surface micro-pitting.

FATIGUED

A structural failure of the filter medium due to flexing caused by cyclic differential pressure.

FERROGRAPHY

An analytical method of assessing machine health by quantifying and examining ferrous wear particles suspended in the lubricant or hydraulic fluid. Particle analysis using magnetism to separate ferrous material to evaluate. Direct reading ferrography and Analytical ferrography are two common types.

FIBER GREASE

A grease with a distinctly fibrous structure, which is noticeable when portions of the grease are pulled apart.

FILM STRENGTH

Property of a lubricant that acts to prevent scuffing or scoring of metal parts.

FILTER

Any device or porous substance used as a strainer for cleaning fluids by removing suspended matter.

FILTER EFFICIENCY

Method of expressing a filter’s ability to trap and retain contaminants of a given size.

FILTER ELEMENT

The porous device which performs the actual process of filtration.

FILTER HEAD

An end closure for the filter case or bowl that contains one or more ports.

FILTER HOUSING

A ported enclosure that directs the flow of fluid through the filter element.

FILTER LIFE TEST

A type of filter capacity test in which a clogging contaminant is added to the influent of a filter, under specified test conditions, to produce a given rise in pressure drop across the filter or until a specified reduction of flow is reached. Filter life may be expressed as test time required to reach terminal conditions at a specified contaminant addition rate.

FILTER MEDIA (DEPTH)

Porous materials which primarily retain contaminants within a tortuous path, performing the actual process of filtration.

FILTER MEDIA (SURFACE)

Porous materials which primarily retain contaminants on the influent face, performing the actual process of filtration.

FILTERABILITY

Measure of filter-clogging tendency caused by resident particles or precipitates within a new, clean lubricant.

FILTRATION

The physical or mechanical process of separating insoluble particulate matter from a fluid, such as air or liquid, by passing the fluid through a filter medium that will not allow the particulates to pass through it.

FILTRATION (Beta) RATIO

The ratio of the number of particles greater than a given size in the influent fluid to the number of particles greater than the same size in the effluent fluid.

FIRE POINT (CLEVELAND OPEN CUP)

The temperature to which a combustible liquid must be heated so that the released vapor will burn continuously when ignited under specified conditions.

FIRE-RESISTANT FLUID

Lubricant used especially in high-temperature or hazardous hydraulic applications. Three common types of fire-resistant fluids are: (1) water-petroleum oil emulsions, in which the water prevents burning of the petroleum constituent; (2) water-glycol fluids; and (3) non-aqueous fluids of low volatility, such as phosphate esters, silicones, and halogenated hydrocarbon-type fluids.

FIXED DISPLACEMENT PUMP

A pump in which the displacement per cycle cannot be varied.

FLASH POINT (CLEVELAND OPEN CUP)

The temperature to which a combustible liquid must be heated to give off sufficient vapor to form momentarily a flammable mixture with air when a small flame is applied under specified conditions. (ASTM Designation D 92.)

FLOW, LAMINAR

A flow situation in which fluid moves in parallel lamina or layers.

FLOW, TURBULENT

A flow situation in which the fluid particles move in a random manner.

FLOW CONTROL VALVE

A valve whose primary function is to control flow rate.

FLOW FATIGUE RATING

The ability of a filter element to resist a structural failure of the filter medium due to flexing caused by cyclic differential pressure.

FLOW RATE

The volume, mass, or weight of a fluid passing through any conductor per unit of time.

FLOWMETER

A device which indicates either flow rate, total flow, or a combination of both.

The ability of a filter element to resist a structural failure of the filter medium due to flexing caused by cyclic differential pressure.

FLUID

A general classification including liquids and gases.

FLUID, FIRE RESISTANT

A fluid difficult to ignite which shows little tendency to propagate flame.

FLUID COMPATIBILITY

The suitability of filtration medium and seal materials for service with the fluid involved.

FLUID FRICTION

Friction due to the viscosity of the fluid – internal friction. Molecular resistance to motion of fluids. The higher the viscosity, the more fluid friction. Also called viscous drag.

FLUID OPACITY

Related to the ability of a fluid to pass light.

FLUID POWER

Energy transmitted and controlled through use of pressurized fluid.

FLUOROCARBONS

A class of refrigerant gases used in closed circuit refrigeration system. Also known as CFC’s, they were banned by the 1996 Montreal Protocol, with production to cease in 2030. Divided into 3 classes, based on miscibility with mineral oils and other performance requirements.

FLUSHING

A fluid circulation process designed to remove contamination from the wetted surfaces of a fluid system.

FOAM INHIBITOR

A substance introduced in a very small proportion to a lubricant or a coolant to prevent the formation of foam due to aeration of the liquid, and to accelerate the dissipation of any foam that may form.

FOAMING

A frothy mixture of air and a petroleum product (e.g., lubricant, fuel oil, etc.) that can reduce the effectiveness of the product, and cause sluggish hydraulic operation, air binding of oil pumps, and overflow of tanks or sumps. Foaming can result from excessive agitation, improper fluid levels, air leaks, cavitation, or contamination with water or other foreign materials. The foaming characteristics of a lubricating oil can be determined by blowing air through a sample at a specified temperature and measuring the volume of foam, based on ASTM D 892 test method.

FOUR-BALL EP TEST

A test designed to measure the EP performance of a lubricant under extremely high loading conditions.

FOUR-BALL WEAR TEST

The name is frequently used to describe either of two similar laboratory machines, The Four-Ball Wear Tester. These machines are used to evaluate a lubricant’s anti-wear qualities, frictional characteristics or load carrying capabilities. It derives its name from the four ½” steel balls used as test specimens. Three of the balls are held together in a cup filled with lubricant while the fourth ball is rotated against them.

FOOD GRADE

Lubricant suitable for use in food processing plants and applications. The H1, H2, and H3 designations were created by the USDA and are based on the likeliness the lubricant will contact the food with approval and registration dependent on the ingredients used in the formulation.

FORCE

Any interaction that, when unopposed, will change the motion of an object.

FORCE FEED LUBRICATION

A system of lubrication in which the lubricant is supplied to the bearing surface under pressure.

FORMULATION

A ‘recipe’ for a given type of lubricant.

FREE WATER

That water in an oil reservoir that is separated, and normally below, the oil depending on the fluid’s specific gravity.

FRETTING

Wear phenomenon taking place between two surfaces having oscillatory relative motion of small amplitude.

FRETTING CORROSION

Can take place when two metals are held in contact and subjected to repeated small sliding, relative motions. Other names for this type of corrosion include wear oxidation, friction oxidation, chafing, and brinelling.

FRICTION

The resisting force encountered at the common boundary between two bodies when, under the action of an external force, one body moves or tends to move relative to the surface of the other.

FTIR (Fourier Transform Infrared Spectroscopy)

A test where infrared light absorption is used for assessing levels of soot, sulfates, oxidation, nitro-oxidation, glycol, fuel, and water contaminants.

FULL FLOW FILTER

A filter that, under specified conditions, filters all influent flow.

FULL-FLOW FILTRATION

A system of filtration in which the total flow of a circulating fluid system passes through a filter.

FULL-FLUID-FILM LUBRICATION

Presence of a continuous lubricating film sufficient to completely separate two surfaces, as distinct from boundary lubrication. Full-fluid-film lubrication is normally hydrodynamic lubrication, whereby the oil adheres to the moving part and is drawn into the area between the sliding surfaces, where it forms a pressure — or hydrodynamic — wedge.

FZG TEST (Four Square Gear Test)

A German gear test for evaluating EP properties through systematic increases in loading on a set of green (untreated) gears. This test depicts the relative performance of various greases to perform under conditions similar to the actual mechanical loading conditions to which lubricants are exposed.

GAGE

An instrument or device for measuring, indicating or comparing a physical characteristic.

GALLING

A form of wear in which seizing or tearing of the gear or bearing surface occurs.

GASEOUS CAVITATION

Cavitation caused by (generally) phase change from dissolved to gaseous vapor in low pressure circuits.

GASOHOL

A blend of 10% anhydrous ethanol (ethyl alcohol) and 90% gasoline, by volume. Used as a motor fuel.

GEAR

A machine part which transmits motion and force by means of successively engaging projections, called teeth. The smaller gear of a pair is called the pinion; the larger, the gear. When the pinion is on the driving shaft, the gear set acts as a speed reducer; when the gear drives, the set acts as a speed multiplier. The basic gear type is the spur gear, or straight-tooth gear, with teeth cut parallel to the gear axis. Spur gears transmit power in applications utilizing parallel shafts. In this type of gear, the teeth mesh along their full length, creating a sudden shift in load from one tooth to the next, with consequent noise and vibration. This problem is overcome by the helical gear, which has teeth cut at an angle to the center of rotation, so that the load is transferred progressively along the length of the tooth from one edge of the gear to the other. When the shafts are not parallel, the most common gear type used is the bevel gear, with teeth cut on a sloping gear face, rather than parallel to the shaft. The spiral bevel gear has teeth cut at an angle to the plane of rotation, which, like the helical gear, reduces vibration and noise. These are all examples of Class I gears.

A worm gear consists of a spirally grooved screw moving against a tooth wheel; in this type of gear, where the load is transmitted across sliding, rather than rolling surfaces, compounded oils or EP oils are usually necessary to maintain effective lubrication. This is an example of a Class II gear.

A hypoid gear resembles a spiral bevel gear, except that the pinion is offset so that its axis does not intersect the gear axis; it is widely used in automobiles between the engine driveshaft and the rear axle. Offset of the axles of hypoid gears introduces additional sliding between the teeth, which, when combined with high loads, requires a high-quality EP oil. This is an example of a Class III gear.

GEAR OIL

A high-quality oil with good oxidation stability, load-carrying capacity, rust protection, and resistance to foaming, for service in gear housings and enclosed chain drives. Specially formulated industrial EP gear oils are used where highly loaded, steel gear sets are encountered.

GEARBOX

A casing for gear sets that transmit power from one rotating shaft to another. A gear box has a number of functions: it is precisely bored to control gear and shaft alignment, it contains the gear oil, and it protects gears and lubricants from water, dust, and other environmental contaminants. Gear boxes are used in a wide range of industrial, automotive, and home machinery. Not all gears are enclosed in gear boxes; some are open to the environment and are commonly lubricated by highly adhesive greases.

GENERATED CONTAMINANT

Caused by a deterioration of critical wetted surfaces and materials or by a breakdown of the fluid itself.

GRAPHITE

A crystalline form of carbon having a laminar structure, which is used as a lubricant. It may be of natural or synthetic origin.

GRAVIMETRIC ANALYSIS

A method of analysis whereby the dry weight of contaminant per unit volume of fluid can be measured showing the degree of contamination in terms of milligrams of contaminant per liter of fluid.

GRAVITY

See Specific Gravity, API Gravity.

GREASE

A lubricant composed of an oil or oils thickened with soap, soaps, or other thickeners to a semi-solid or solid consistency.

HARDNESS

The resistance of a substance to surface abrasion.

HEAD

An end closure for the filter case or bowl which contains one or more ports.

HEAT EXCHANGER

A device which transfers heat through a conducting wall from one fluid to another.

HOUSING

A ported enclosure which directs the flow of fluid through the filter element.

HYDRAULIC FLUID

Fluid serving as the power transmission medium in a hydraulic system. The most commonly used fluids are petroleum oils, synthetic lubricants, oil-water emulsions, and water-glycol mixtures. The principal requirements of a premium hydraulic fluid are proper viscosity, high viscosity index, anti-wear protection (if needed), good oxidation stability, adequate pour point, good demulsibility, rust inhibition, resistance to foaming, and compatibility with seal materials. Anti-wear oils are frequently used in compact, high-pressure, and capacity pumps that require extra lubrication protection.

HYDRAULIC MOTOR

A device which converts hydraulic fluid power into mechanical force and motion by transfer of flow under pressure. It is usually provided by rotary mechanical motion.

HYDRAULIC OIL

An oil specially suited for use as either the specific gravity or the API gravity of a liquid.

HYDRAULIC PUMP

A device which converts mechanical force and motion into hydraulic fluid power by means of producing flow.

HYDRAULIC SYSTEM

A system designed to transmit power through a liquid medium, permitting multiplication of force in accordance with Pascal’s Law, which states that “a pressure exerted on a confined liquid is transmitted undiminished in all directions and acts with equal force on all equal areas.” Hydraulic systems have six basic components: (1) a reservoir to hold the fluid supply; (2) a fluid to transmit the power; (3) a pump to move the fluid; (4) a valve to regulate pressure; (5) a directional valve to control the flow, and (6) a working component – such as a cylinder and piston or a shaft rotated by pressurized fluid – to return hydraulic power into mechanical motion. Hydraulic systems offer several advantages over mechanical systems: They eliminate complicated mechanisms such as cams, gears, and levers; are less subject to wear; are usually more easily adjusted for control of speed and force; are easily adaptable to both rotary and liner transmission of power; and can transmit power over long distances and in any direction with small losses.

HYDRAULICS

Engineering science pertaining to liquid pressure and flow.

HYDROCARBONS

Chemical compounds of hydrogen and carbon. Carbon atoms form the skeleton of the hydrocarbon molecule. Three principal petroleum types exist from crude: paraffins, naphthenes, and aromatics. Aromatics are more reactive as they are unsaturated molecules. Petroleum consists chiefly of hydrocarbons.

HYDROCRACKING

Processing method that requires more severe conditions for hydro processing to convert aromatics and naphthenes and linear and branched paraffins.

HYDRODYNAMIC LUBRICATION

A system of lubrication in which the shape and relative motion of the sliding surfaces causes the formation of a fluid film having sufficient pressure to separate the surfaces.

HYDROFINISHING

A process for treating raw extracted base stocks with hydrogen to saturate them for improved stability.

HYDROLYSIS

Breakdown process that occurs in anhydrous hydraulic fluids as a result of heat, water, and metal catalysts (iron, steel, copper, etc.)

HYDROLYTIC STABILITY

Ability of additives and certain synthetic lubricants to resist chemical decomposition (hydrolysis) in the presence of water.

HYDROMETER

An instrument for determining either the specific gravity of a liquid or the API gravity.

HYDROPEROXIDE

Reactive hydrocarbon produced through chemical change of stable hydrocarbons during the process of oxidation.

HYDROPHILIC

Compounds with an affinity for water.

HYDROPHOBIC

Compounds that repel water.

HYDROSTATIC LUBRICATION

A system of lubrication in which the lubricant is supplied under sufficient external pressure to separate the opposing surfaces by a fluid film.

HYPOID GEAR LUBRICANT

A gear lubricant having extreme pressure characteristics for use with a hypoid type of gear as in the differential of an automobile.

HYPOID GEARS

Gears in which the pinion axis intersects the plane of the ring gear at a point below the ring-gear axle and above the outer edge of the ring gear, or above the ring-gear axle and below the outer edge of the ring gear.

ILSAC

The International Lubricant Standardization and Approval Committee (ILSAC) is a joint committee of AAMA and JAMA members that assists in the development of new minimum oil performance standards.

IMAGE ANALYZER

A sophisticated microscopic system involving a microscope, a television camera, a dedicated computer, and a viewing monitor similar to a television screen.

IMMISCIBLE

Incapable of being mixed without separation of phases. Water and petroleum oil are immiscible under most conditions, although they can be made miscible with the addition of an emulsifier.

IMPURITY

Anything that doesn’t belong in the lubricant.

INCOMPATIBILITY

Two lubricating greases show incompatibility when a mixture of the two shows physical properties or service performance markedly inferior to those of either of the greases before mixing.

INDICATOR

A device which provides external evidence of sensed phenomena.

INDICATOR, DIFFERENTIAL PRESSURE

An indicator which signals the difference in pressure between two points, typically between the upstream and downstream sides of a filter element.

INDICATOR, PRESSURE

An indicator that signals pressure conditions.

INFLUENT

The fluid entering a component.

INFRARED SPECTRA

A graph of infrared energy absorbed at various frequencies in the additive region of the infrared spectrum. The current sample, the reference oil and the previous samples are usually compared.

INFRARED SPECTROSCOPY

An analytical method using infrared absorption for assessing the properties of used oil and certain contaminants suspended therein. See FTIR.

INGESTED CONTAMINANTS

Environmental contaminant that ingresses due to the action of the system or machine.

INGRESSION LEVEL

Particles added per unit of circulating fluid volume.

INHIBITOR

A substance (additive) which slows or prevents chemical reactions, such as oxidation or corrosion.

IN-LINE FILTER

A filter assembly in which the inlet, outlet and filter element axis are in a straight line.

INSIDE-MOUNTED SEAL

A mechanical seal located inside the seal chamber with the pumped product’s pressure as its OD.

INSOLUBLES

Particles of carbon or agglomerates of carbon and other material. Indicates deposition or dispersant drop-out in an engine. Not serious in a compressor or gearbox unless there has been a rapid increase in these particles.

INTENSIFIER

A device which converts low pressure fluid power into higher pressure fluid power.

INTERCOOLER

A device which cools a gas between the compressive steps of a multiple stage compressor.

INTERFACIAL TENSION (IFT)

The energy per unit area present at the boundary of two immiscible liquids. It is usually expressed in dynes/cm (ASTM Designation D 971.)

INTERNATIONAL COUNCIL FOR MACHINERY LUBRICATION (ICML)

A vendor-neutral, not-for-profit organization founded to serve global industry as the world-class authority on machinery lubrication that advances the optimization of asset reliability, utilization and costs.

INVERT EMULSION

A water in oil lubricant mixture, often used to create fire resistance hydraulic oils and various metal process fluids.

ISO

International Standards Organization, sets viscosity reference scales.

ISO GRADE

International Standards Organization viscosity grade. A measure of kinematic viscosity at 40°C. Each ISO grade corresponds to the midpoint of a viscosity range expressed in centistokes (cSt), with a defined viscosity tolerance range of +- 10%.

ISO SOLID CONTAMINATION CODE (ISO 4406-99)

A code assigned on the basis of the number of particles per unit volume greater than 4, 6, and 14 micrometers in size. Range numbers identify each increment of the particle population for a spectrum of levels.

ISO STANDARD 4021

The accepted procedure for extracting samples from dynamic fluid lines.

JOURNAL

That part of a shaft or axle that rotates or angularly oscillates in or against a bearing or about which a bearing rotates or angularly oscillates.

JOURNAL BEARING

A sliding type of bearing having either rotating or oscillatory motion and in conjunction with which a journal operates. In a full or sleeve type journal bearing, the bearing surface is 360° in extent. In a partial bearing, the bearing surface is less than 360° in extent, i.e., 150°, 120°, etc.

KARL FISCHER TITRATION TEST

A test to measure the water content (in ppm) in oils, ASTM D1744 & D4928. Widely considered the most accurate test for water quantification and measures all phases of water in oil (dissolved, emulsified, and free).

KINEMATIC VISCOSITY

Noted as the time required for a fixed amount of oil to flow through a capillary tube under the force of gravity. The unit of kinematic viscosity is the stoke or centistoke (1/100 of a stoke). Kinematic viscosity may be defined as the quotient of the absolute viscosity in centipoises divided by the specific gravity of a fluid. ASTM D 3448.

L10 LIFE- L 10

The life that 90% of bearings should be expected to achieve for a given application and conditions.

LACQUER

A deposit resulting from the oxidation and polymerization of fuels and lubricants when exposed to high temperatures. Like, but harder, than varnish.

LAMINAR PARTICLES

Particles generated in rolling element bearings which have been flattened out by rolling contact.

LOAD-CARRYING CAPACITY

The property of a lubricant to form a film on the lubricated surface, which resists rupture under given load conditions. Expressed as maximum load the lubricated system can support without failure or excessive wear.

LOAD-WEAR INDEX (LWI)

Measure of the relatively ability of a lubricant to prevent wear under applied loads; it is calculated from data obtained from the Four Ball EP Method. Formerly called mean Hertz load.

LUBRICANT

Any substance, interposed between two surfaces in relative motion, which reduces the friction or wear of the surfaces.

LUBRICATION

The control of friction and wear by the introduction of a friction-reducing film between moving surfaces in contact. The lubricant used can be a fluid, solid, or plastic substance.

LUBRICATOR

A device which adds controlled or metered amounts of lubricant into a pneumatic system.

LUBRICITY

Ability of an oil or grease to lubricate; also called film strength.

MAGNETIC

A separator that uses a magnetic field to attract and hold ferromagnetic particles.

MAGNETIC FILTER

A filter element that, in addition to its filter medium, has a magnet or magnets incorporated into its structure to attract and hold ferromagnetic particles.

MAGNETIC PLUG

Strategically located in the flow stream to collect a representative sample of wear debris circulating in the system: for example, engine swarf, bearing flakes, and fatigue chunks. The rate of buildup of wear debris reflects degradation of critical surfaces.

MANIFOLD

A filter assembly containing multiple ports and integral relating components which services more than one fluid circuit.

MANIFOLD FILTER

A filter in which the inlet and outlet port axes are at right angles, and the filter element axis is parallel to either port axis.

MEDIA MIGRATION

Material passed into the effluent stream composed of the materials making up the filter medium.

MEDIUM

The porous material that performs the actual process of filtration. The plural of this word is “media”.

METAL OXIDES

Oxidized ferrous particles which are very old or have been recently produced by conditions of inadequate lubrication. Trend is important.

METAL SOAP

Thickening agent used to stiffen lubrication oils in grease formulation. Composed of a metal ion, a fatty compound, and an acid.

METALLOPHILLIC

Having an affinity for metal surfaces.

MICELLE

A loosely bound aggregation of atoms, ions (electrically charged atoms), or molecules, forming a colloidal particle – i.e., one of several ultramicroscopic particles dispersed through some continuous medium.

MICROMETER (µm)

See Micron.

MICRON