iLearnReliability™ Learning Management System

You must educate everyone if you wish to change the culture. Everyone educated, motivated, and aligned. iLearnReliability will enable you to achieve that goal.

There is a disagreement in the reliability world

It is said that winning the support of the people within an organization is half of the challenge in achieving a reliable plant.

But many people, with experience, disagree. They would argue it is more like 75% of the challenge.

Focused training, such as Asset Reliability Practitioner® [ARP] and detailed condition monitoring training, tend to only focus on the specialists working in those areas. That’s great, but it is not enough.

You must have a way of creating awareness, buy-in, and enthusiasm for the program in order to have success. You must demystify the technologies and the strategy. Everyone must understand “what’s in it for me”.

In short, you must change the culture to change behavior. iLearnReliability was developed for that purpose.

What is iLearnReliability?

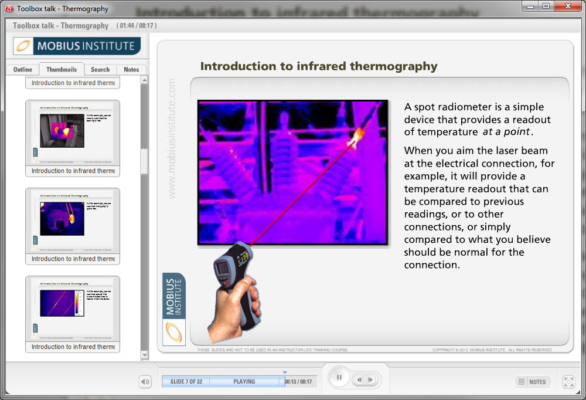

iLearnReliability is a web-based learning management system (LMS) that provides training on a broad range of topics for everyone in the plant. There are “toolbox talks”, “manager briefings”, “skills training” and other modules that are designed for different audiences. In many cases, the same topic is covered many times because different people need a different level of depth and they have different interests: business benefits, the demystification of a technology, “how-to”, etc.

You can take the training as many times as you like. People who take an interest can learn the topics at a deeper level. New employees can get up to speed quickly. There are so many benefits.

And one of the key benefits is that you will have everyone speaking the same language. Everyone will understand the goals, they will understand how they can contribute, they will be familiar with the terminology – everyone will pull in the same direction.

iLearnReliability is a series of e-learning mini-courses

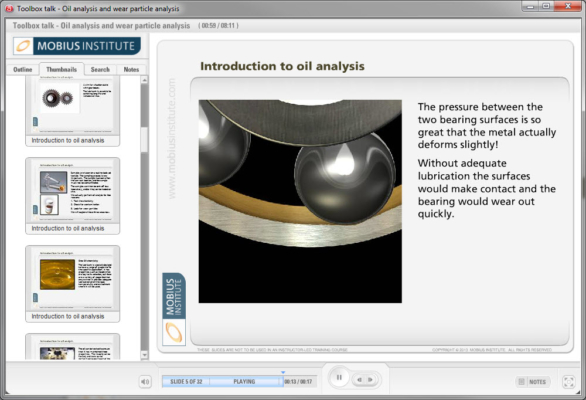

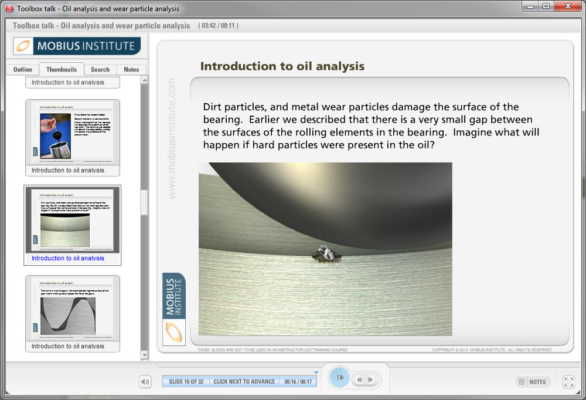

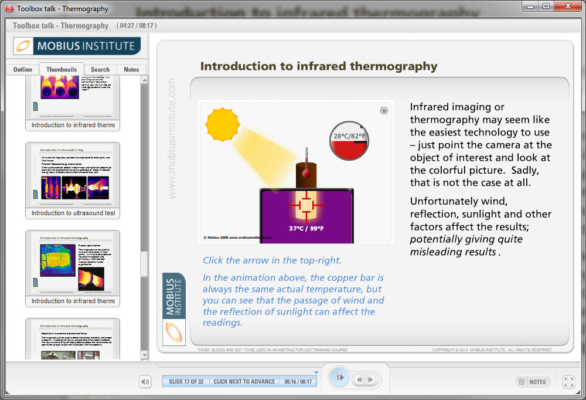

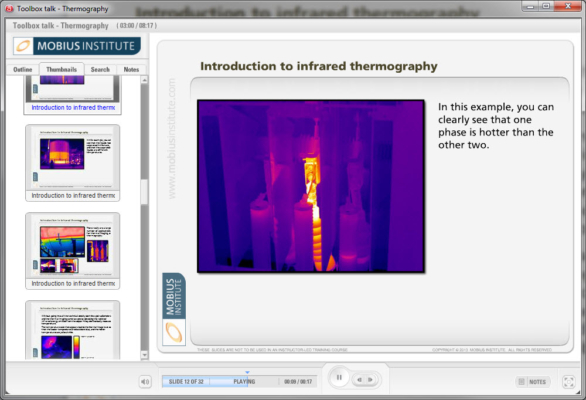

Some courses are very short. Some are quite long. Each one is narrated, slide-by-slide, filled with graphics, illustrations, animations, and in many cases, interactive simulations.

Our animations make it easier to understand and more engaging – people enjoy learning with iLearnReliability.

Our simulations actually allow the participant to engage with the lesson. In this case, the camera can be moved so you can see the hot-spot!